I have touch on this topic in December 2010 in the title of Sawdust Drying . In many cases material needs to be dried to certain acceptable Moisture Content before it can proceed to the next stage of manufacturing .

In my visits to many plant , I have seen too many mistakes made in the selection of drying system , either wrong fuel are used , wrong design of furnace , wrong design of dryer , wrong design of conveying system for input and output of materials and etc . This mistakes cause many other problems down the line especially during pelletisation not mentioning high cost of drying . Make no mistake , you cannot have good system if you do not have proper knowledge of drying and combustion . That is why drying system are expensive because it will saves you money later and in some cases a matter of do or die .

Drying Efficiency

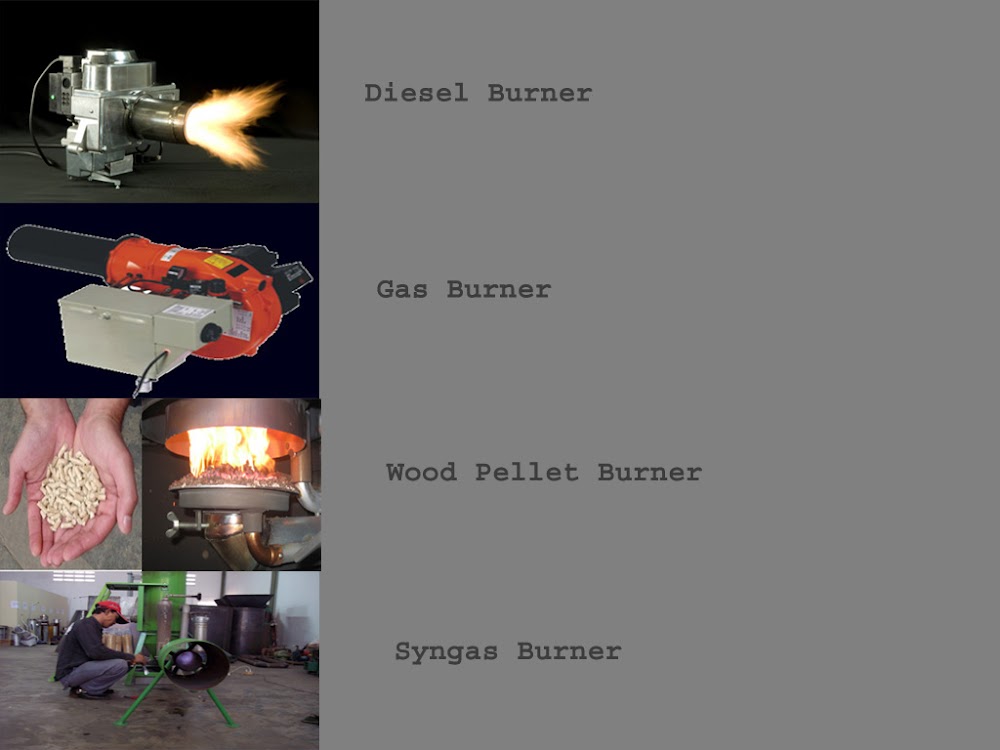

Drying for pelleting process are normally done with direct chanelling of hot flue gas into the drum dryer where the hot air are in direct contact with the material to be dried . This process of direct contact are of highest efficiency as compared to indirect heating with a heat exchanger . Depending on material , moisture content of the material and structure of the material , the hot flue gas input temperature can be as high as 800º celcius . The higher the temperature , the faster the material are being dried and you will get higher output from the drum dryer otherwise the drying section will become bottleneck . Consistent temperature from the furnace to the dryer are also important so that the Moisture of Biomass dried is consistent . To achieve consistency and narrow range of Moisture , firing into furnace or dryer need to be consistent , this can be achieve by having good Burner .

Drying Cost

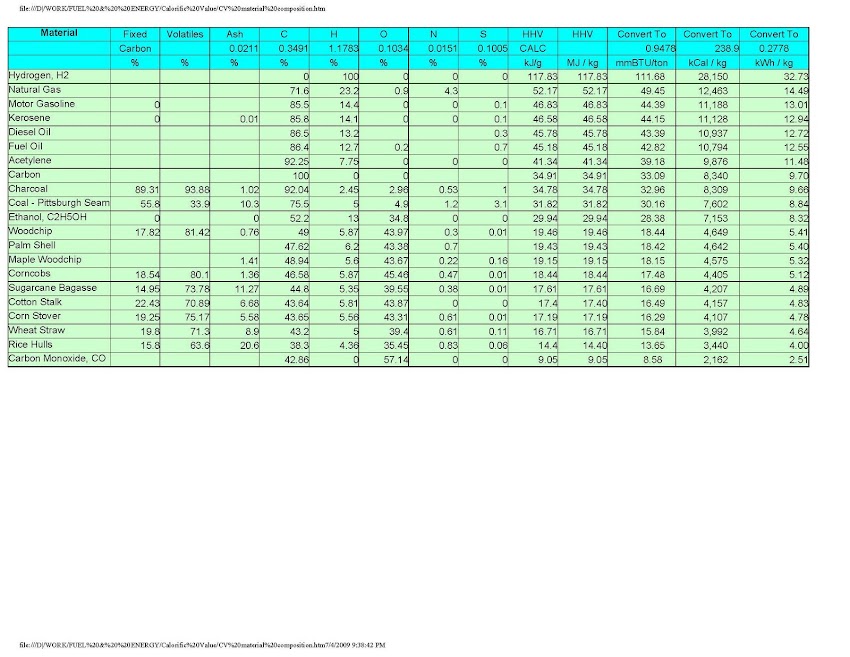

Many a times this was overlook , everything we sell have a selling price and it also come with a cost . Similarly in wood pelleting , there is cost to manufacturing of wood pellet , and to those who use wet sawdust or even EFB , there will be need for drying , this is one section which is often overlook . Good cost structure will be drying cost of below RM20 / MT of dried raw material . How do we achieve this :

1 ) use low cost material like timber offcut , woodchip , EFB , Palm Fibre etc

2 ) use high efficiency pellet burner because you are producing pellet

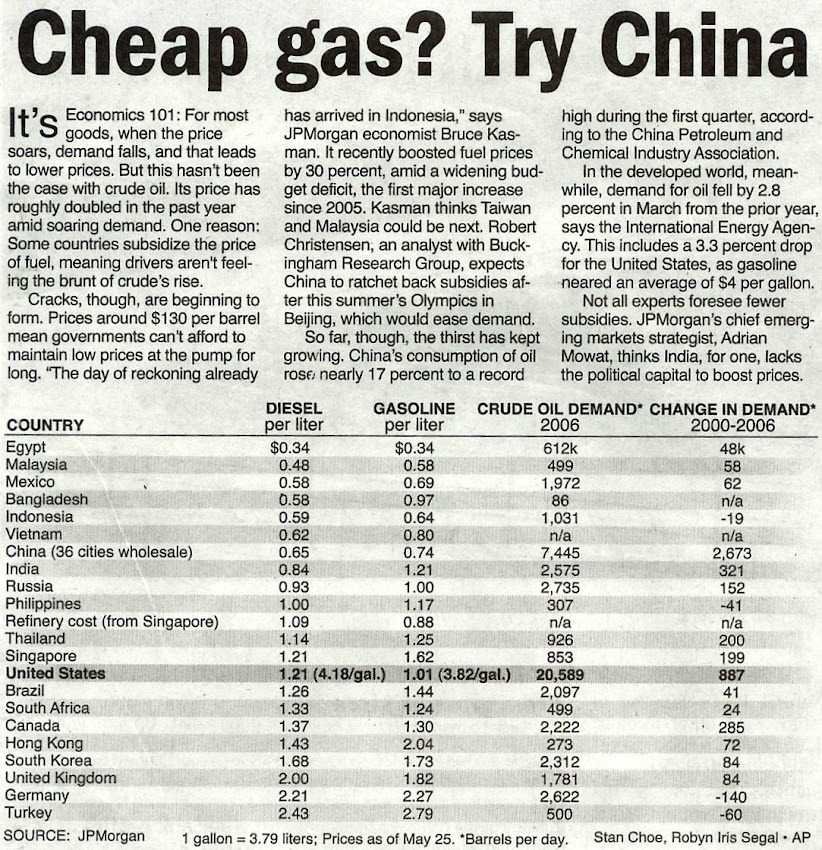

3 ) do not use electricity , gas or diesel burner , you calculate the cost yourself to find out

That being said , the planning of Good Drying System is pertinent to keep the cost low so that there will be profit in the selling of pellet . If you dry your material above RM50 / MT then this business will be unprofitable .

In short it is not easy to keep cost low as currently for any fuel there is cost involved , selection of correct drying system are important .

Drying Quality

During pelleting process , consistent Moisture Content of material input are important to give consistent quality of pellet output , otherwise one minute you will get good and the next minute bad quality pellet . Therefore dryer must have flexibility to ensure Consistent MC for biomass output from dryer .

During pelleting process , consistent Moisture Content of material input are important to give consistent quality of pellet output , otherwise one minute you will get good and the next minute bad quality pellet . Therefore dryer must have flexibility to ensure Consistent MC for biomass output from dryer .

For your information , any sawdust or even EFB will have sand and stone in it , too much of it will increase the ash content of pellet and thus pellet price will be affected . A good dryer will have system to remove partial of the sand and stone . Removal of sand and stone will also prolong the life of roller and die during pelleting process .

3 of the above factor are important in the selection of the correct dryer . Wrong selection will cause the followings :

1 ) Under or Over Capacity of dryer

2 ) Low temperature input will cause slow drying

3 ) Inconsistent temperature cause fluctuation in drying thus MC of biomass dried will not be consistent

4 ) Wrongly build furnace do not give enough heat input to dryer causing under utilisation of dryer

5 ) Wrong air flow of hot flue gas are not sufficient for drying of biomass

6 ) Wrong design of input and output conveyors reduce the efficiency of drying

7 ) Non Flexibility of dryer controller make it difficult to get good drying results

8 ) Wrong biomass used for firing , increase cost of drying , whole project not viable

9 ) Manual feeding of biomass fuel in big furnace are not recommended as labour incur cost and optimum drying are not achieved

10 ) Inconsistent MC of biomass dried cannot be pelletise into good quality pellet

11 ) Too much sand and stone will jam the Pellet Mill and damage other parts

and many many more .

Make sure Dryer are selected correctly .

Drum Dryer selection are important , many factor affect the cost of the dryer , in this case we believe Drum Dryer Size of Diameter 1.5 meter X Length 9 meter should be enough to dry 2 TPH of sawdust .

Drum Dryer selection are important , many factor affect the cost of the dryer , in this case we believe Drum Dryer Size of Diameter 1.5 meter X Length 9 meter should be enough to dry 2 TPH of sawdust .