Wood Pellet Burner / EFB Pellet Burner

Availability of wood pellet in the Malaysia Market have enable the introduction of Wood Pellet Burner .

Wood Pellet Burner can be categorised into small home use type ( typically below 100kw ) or big unit for replacing diesel / gas burner for industrial use ( from 300kw to 2,500kw )

Small Wood Pellet Burner

With consumption of over 10 million ton wood pellet in 2010 , Europe is the biggest market of wood pellet . Usage of wood pellet burner to replace fuel oil / diesel / gas burner have been taking place for the last 10 years or more . Therefore wood pellet burner produced are very technologically advance .

The burner have characteristic as follows :

1 ) Fully automated - even with modulated firing

2 ) lambda sensor - oxygen sensor in the flue gas , to adjust air input for efficient combustion

3 ) > 90% efficiency - very close to diesel / gas burner fuel to heat conversion

4 ) Automatic Dust cleaning mechanism

5 ) automatic ignition , sleep mode , timer , remote control , mobile phone control , etc

6 ) easy conversion from oil burner to wood pellet burner without modification

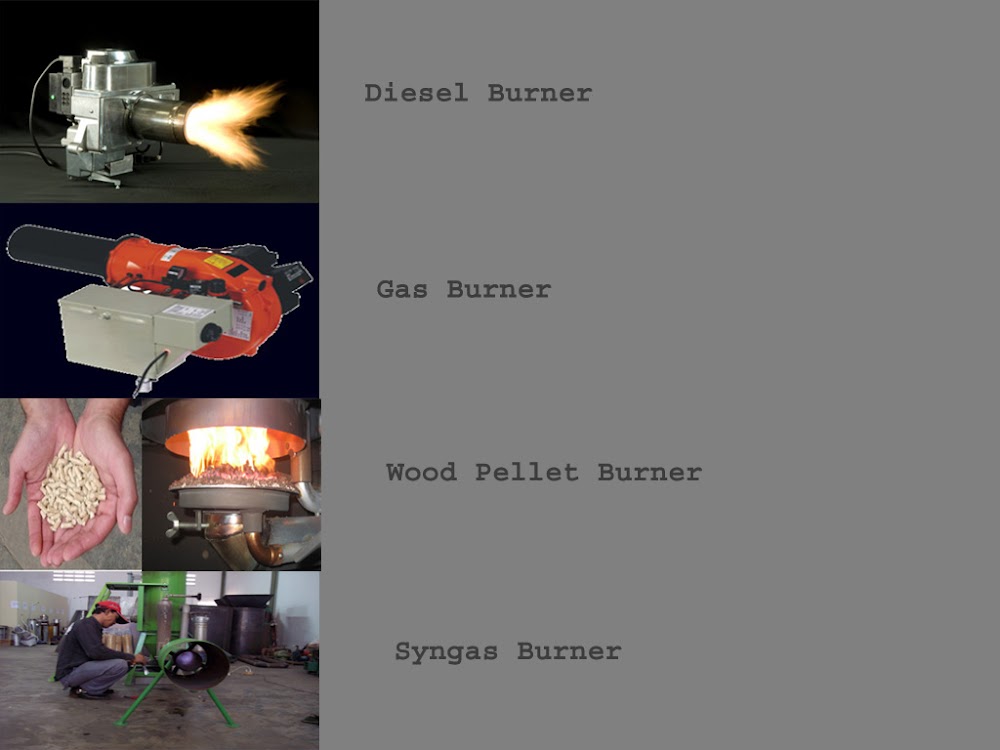

Changeover from Diesel Burner to Wood Pellet Burner

Industrial Wood Pellet / EFB Pellet Burner

We will be launching this Burner in a month or two which have the following specification :

1 ) Replacement of diesel burner with capacity of 300kw ( 250,000 kCal/hr ) to 2,500kw ( 2 Million kCal / hr ) . This is similar to diesel burner firing into a 0.5 ton per hour to 4 ton per hour steam boiler .

2 ) Control is by pressure sensor similar to diesel burner automatic firing although modulation firing are not available currently .

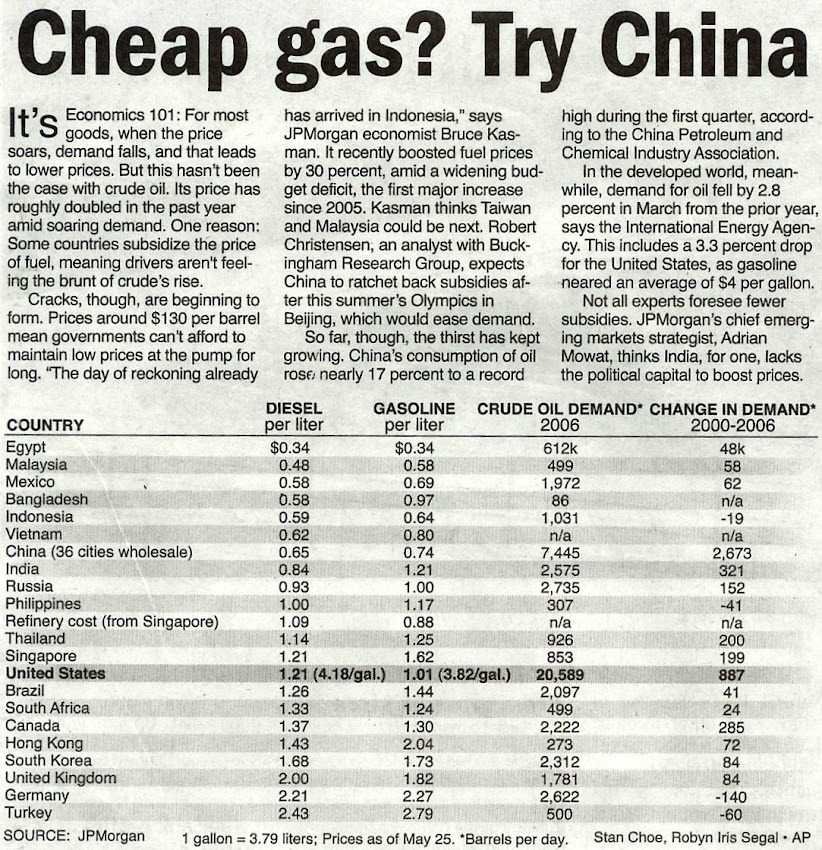

3 ) Savings in fuel consumption are from RM37/hour for 300kw unit and RM298 / hour for 2,500kw unit .

Cost of the Burner from RM40,000 to RM120,000 . Payback in 6 months for the small unit and 4 months for the big unit . Gasifier of similar capacity cost 4 to 10 times more .

Wood Pellet Burner - 200MW / 180,000 Kcal / hour

THIS IS ONE OF THE MAIN REASON WE HAVE BEEN HOLDING BACK ON OUR GASIFIER PROMOTION FOR THERMAL APPLICATION .

By far and large , wood pellet due to it's size consistency , high and consistent calorific value , availability , stable price & eco friendly fuel are very suitable for the replacement of diesel or gas .

START helping the environment to reduce emission of CO2 ,

DO YOUR PART .