COMPARISON

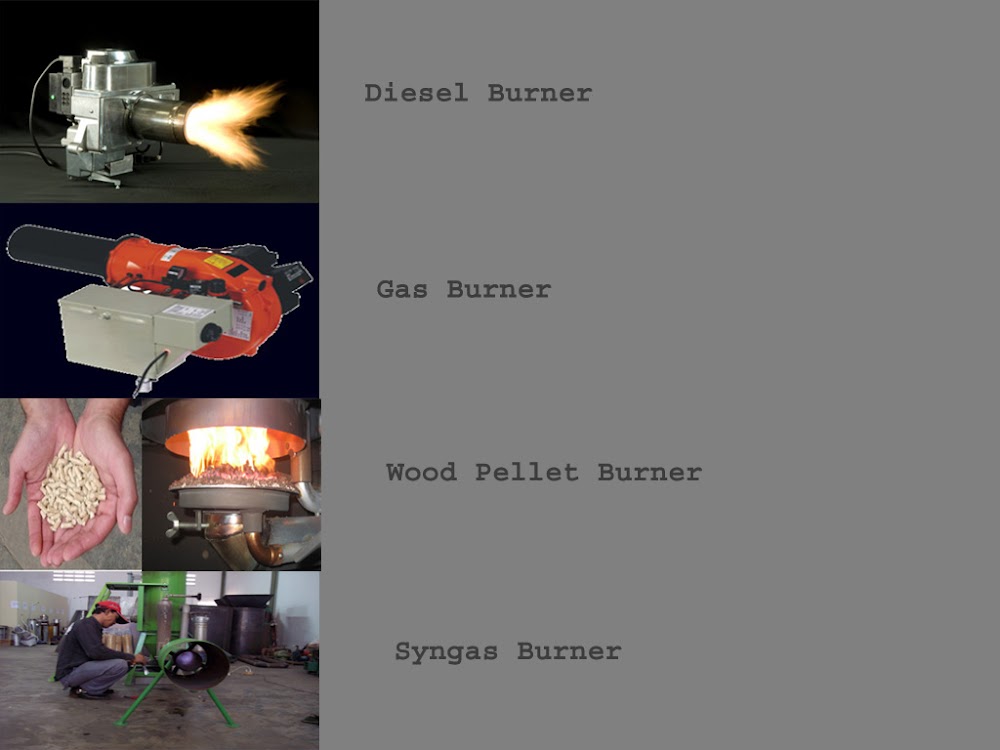

I believe we have talk in length on Wood Pellet Burner and Gasifier , but question come to mind what is the difference between this 2 .

I believe we have talk in length on Wood Pellet Burner and Gasifier , but question come to mind what is the difference between this 2 .

I list the comparison between the 2 below .

I will explain in details the pro & con for wood pellet burner and gasifier .

Pricing

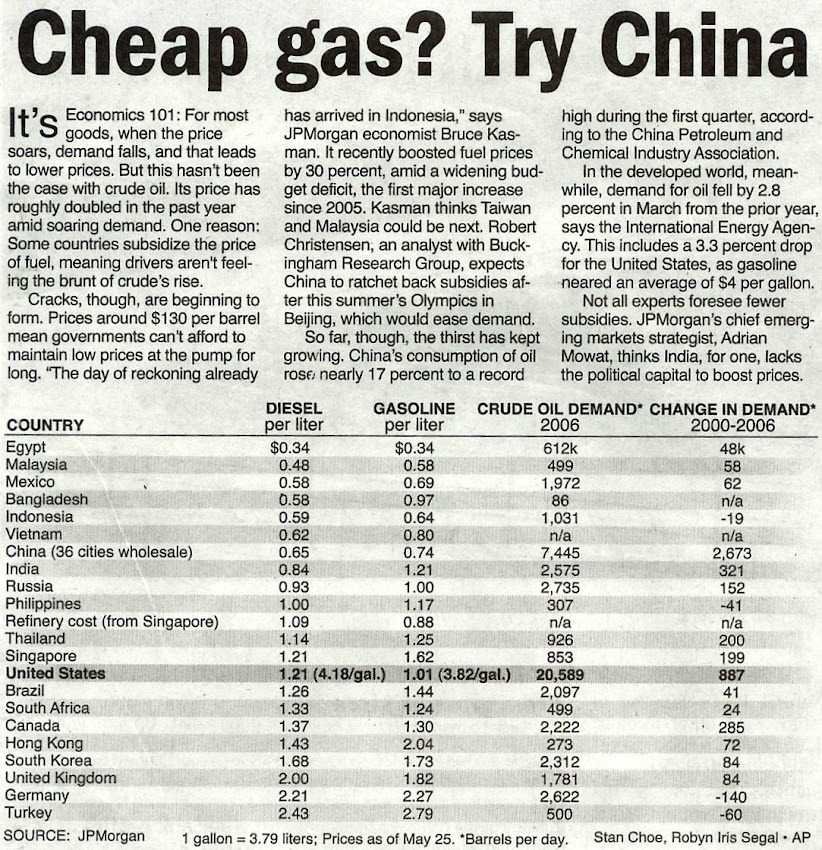

After countless conversation with so many potential user who is looking for change , the big stumbling block is PRICING AND DISTRUST for new technology .

How cheap can biomass and application equipment goes , no body knows , for now this is the price and there is payback calculation for you to judge .

After considering the price , customer will ask can I see how it works , SEEING IS BELIEVING !!! AGREED .

This problem come about due to so many fly by night equipment provider who have give this industries a bad name . So once it is spoilt , it will be very difficult to make amend .

I append below according to categories , the differences :

Technicality

As mentioned above technical specification for Gasifier are much more higher than simple Wood Pellet Burner . Therefore so many of the gasifier that came up in the market in Malaysia are not successful as we Malaysian have not yet achieve the speciality in Gasification . Unfortunately some potential investor suffer due to lack of information and sweet talk by good marketers .

Wood Pellet Burner are very simple machine with some ingenious controls and design which need very simple maintenance , therefore it can be so successful in Europe due to it's simplicity .

WHO need a sophisticated machine to do the same job for 5 times the price ! ! !

Efficiency

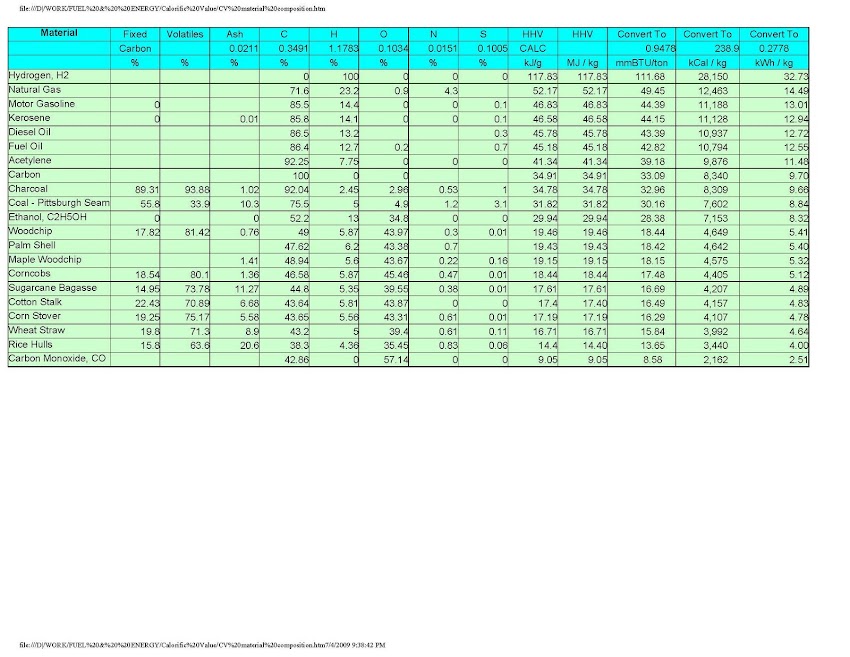

90 % Vs 75% , why ?

a ) all biomass are turned to ash , only the ash weight and loss of heat during combustion , therefore loss is only 10% for Wood Pellet Burner . Whereas for Gasifier , big portion ( 20 % ) are turned to carbon and therefore efficiency is only 75 % with heat loss . Unless you want to sell the carbon !!!

b ) In Wood Pellet Burner all the biomass are combusted in optimum Air Fuel Ratio ( AFR , 1 kg wood pellet to 5 kg of air ) and immediately the heat are channel into boiler / furnace , loss will be low as this happen instantaneously . Whereas for Gasifier it goes through a few process , pyrolysis , gasfication , syngas cleaning then only the syngas are channel to burner for burning . Moreover you must have very good burner to control the AFR otherwise you will not get good optimum combustion , causing more loss in efficiencyAsh / Carbon Discharge , Operator Needed and Cleaning / Servicing

As Gasification produce carbon which is higher in weight ( 20 % ) compared to fully combusted biomass where it only produce ash ( below 1% for wood pellet ) , therefore Wood Pellet Burner are much more simpler compared to Gasifier .

Moreover more monitoring are needed for Gasifier to ensure Gasification are optimum which is difficult to achieve consistently especially so if the biomass feed are inconsistent .

Gasifier end product is Syngas which is high in Tar level , to ensure burner are not clog , the syngas need to be clean , with scrubber and filtering , which in the end ( once a week , depending on system ) , need to be clean and service otherwise the Gasifier will stop working .

Control of Burner

Wood Pellet Burner as mentioned above are very simple but with good design equipment . Control in the case of firing into Boiler would be very simple , just fire into the boiler , when pressure in the boiler are reach the burner will go into sleep mode and the burner will fire again when pressure drop to lower level set , simply similar to diesel burner , that is why it is so easy .

In Gasifier case , the fuel for firing into boiler is Syngas , sometimes you get good composition syngas , sometimes you do not , so control will be difficult or it would not be optimum or lower in efficiency .

Pros for Gasifier - Application , Flexibility of Burner Positioning , Usefulness of Carbon and Cleanliness of Combustion

Unless you find you need this Pros , these are small benefit you need to forego to attained the pros of wood pellet burner .

You cannot get perfection unless you are willing to pay very high price .

REMEMBER GASIFIER IS 5 TIMES MORE EXPENSIVE !!!