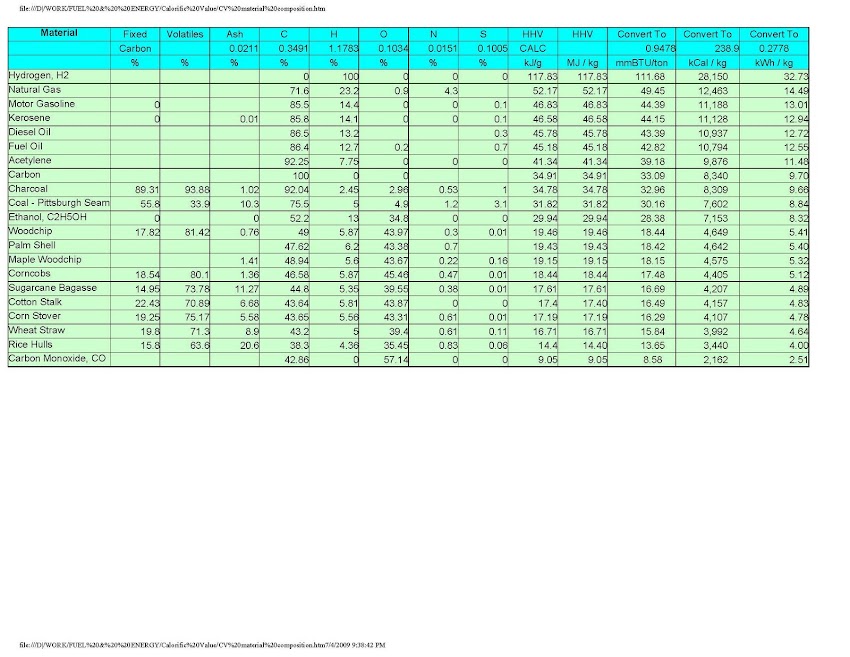

Choose Biomass that is low in $ / kCal instead of $ / kg .

Malaysia Biomass

Malaysia Biomass . Biomass Calorific Value are very important in the selection of fuel for combustion and gasification . This is due to Energy content per kg of biomass . You can have very cheap biomass such as EFB but due to it's Moisture Content of 65% and so Calorific Value will be low at 1,400 kCal / kg . Moreover during combustion , silica ash will scale the tube causing reduction in efficiency of boiler and fly ash is a concern with Environment Authority .

Typically there are plenty of biomass materials in Malaysia which are able to be used to replace fossil fuel . Malaysia Biomass material available are as follows :

Material Calorific Value Moisture Content

1 ) Woodchip 3,500 Kcal / kg 25 %

2 ) Sawdust 3,500 Kcal / kg 25 %

3 ) Empty Fruit Bunch 1,400 Kcal / kg 65 %

4 ) Rice Husk 3,000 Kcal / kg 10 %

The above Malaysia Biomass is among the lowest in $ / kCal ( high in energy density per RM ) and available in abundance in Malaysia .

I did not include wood pellet as it is to my knowledge still not available in Malaysia ( I would like to know who have it ? ) . This biomass will be in the future replace wood chip due to very standardise size and quality of heat output .

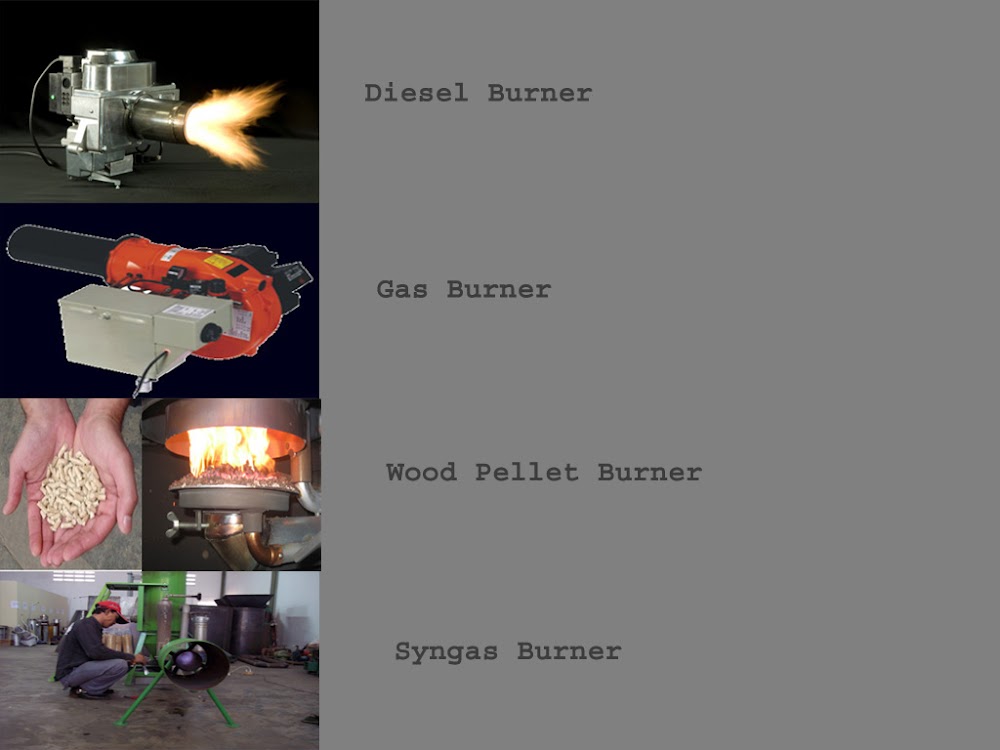

The above mentioned biomass are which I will elaborate more due to current available technology for full combustion which will emit no smoke . These is done by converting the said biomass to syngas .

The problem for these change over to biomass thermal application is the lack of suitable biomass material , inconsistent quality supply of biomass , system for combustion , high delivery cost , long perceived thinking that biomass emits heavy smoke , storage problem for user and etc .

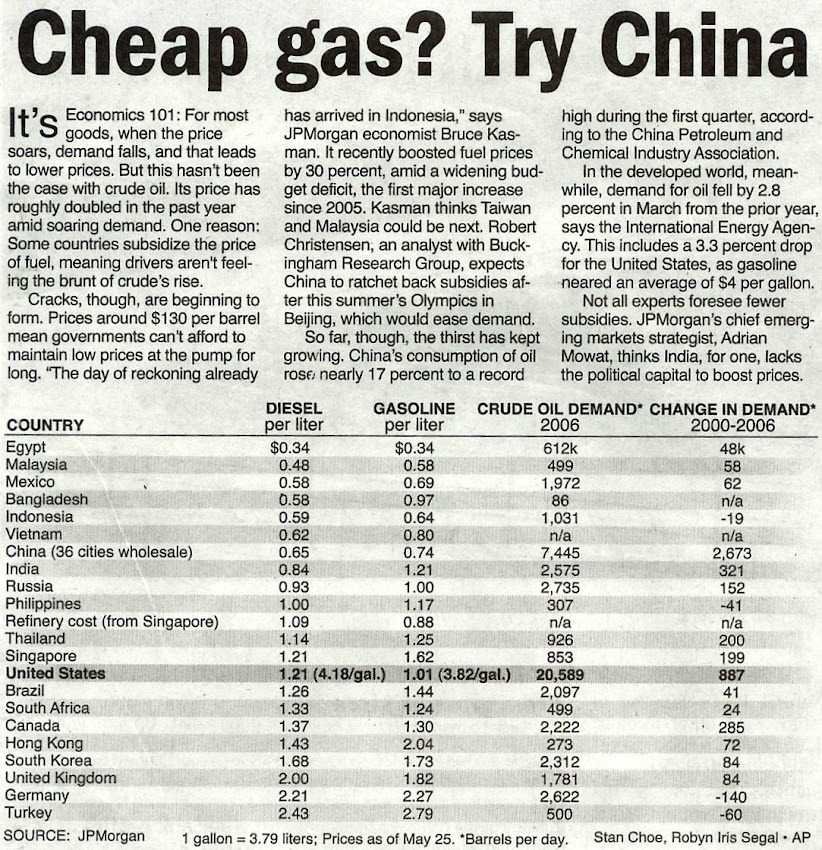

For the record , the favourite , Diesel ( Calorific Value - 8,770 Kcal / liter ) was the thermal fuel in Malaysia which is widely available and cheap for the last decades . As it is now a heavy burden to many industries , it is time to change to biomass not only that it is green , it will also enable industries to save on high fuel cost .

Here I will go into details for Wood Chip as the preferred biomass due to reason i will mention below .

Wood Chip

is a product derived from sawmill waste . Quite recently in the last 1 year or so , plenty of wood chip production come on stream due to demand from MDF and Particle Board Manufacturer . But now due to it's limited supply , price have moved up and stablilised at around RM150 / ton to RM200 / ton depending on delivery cost . I am suggesting this biomass material ( Wood Chip Only ) to be used as fuel for gasifier due to

a ) year round availablity

b ) easy delivery

c ) lower cost of transportation

d ) ease of handling

e ) lesser contamination at user factory

and etc .

At the price given it will work out to RM0.061 per mmCalorie ( RM15.47 / mmBTU ) compared to diesel when price is RM3.20 / liter at RM0.354 per mmCalorie ( RM89.18 / mmBTU ) . From this comparison you can see that wood chip is only 17 % of diesel .

WOW , did anyone realise this ???

Yes , I did claim that there is 70 % savings only for change over to gasifier , this is due to some loss of heat during gasification process , in some unefficient gasifier you might get even lower savings in the range of 50 % to 60 % only .

The reason I did not elaborate on EFB ( Empty Fruit Bunch ) eventhough it is cheap is because it need to be further process and the calorific value is very low . Another reason is that my proposed gasifier system might not be able to take these fuel or I would rather say efficiency will be very low . There is Ah Niau and Ah Kau that would say , what savings of 70% , mine can do at least 90 % savings with EFB as it is cheap , HAHAHAHHAHAH , BE CAREFUL .

But I promise you if you can wait a few years ( or your factory can wait for a few years ) I will try to bring 90 % to you . These is when Oil at USD200 per barrel and EFB can be use .

So the saying goes like this , YOU GET WHAT YOU PAID FOR !!!

ACT NOW !!! AND GET BACK YOUR INVESTMENT WITHIN 1 YEAR ..........

The next blog will be on choosing the right gasifier . Am I up to it ???

Bye for now .