BOILER

The boiler are design for winter heating in Europe and are suitable for industries which need hot water e.g hotel hot water supply and industrial cooking .

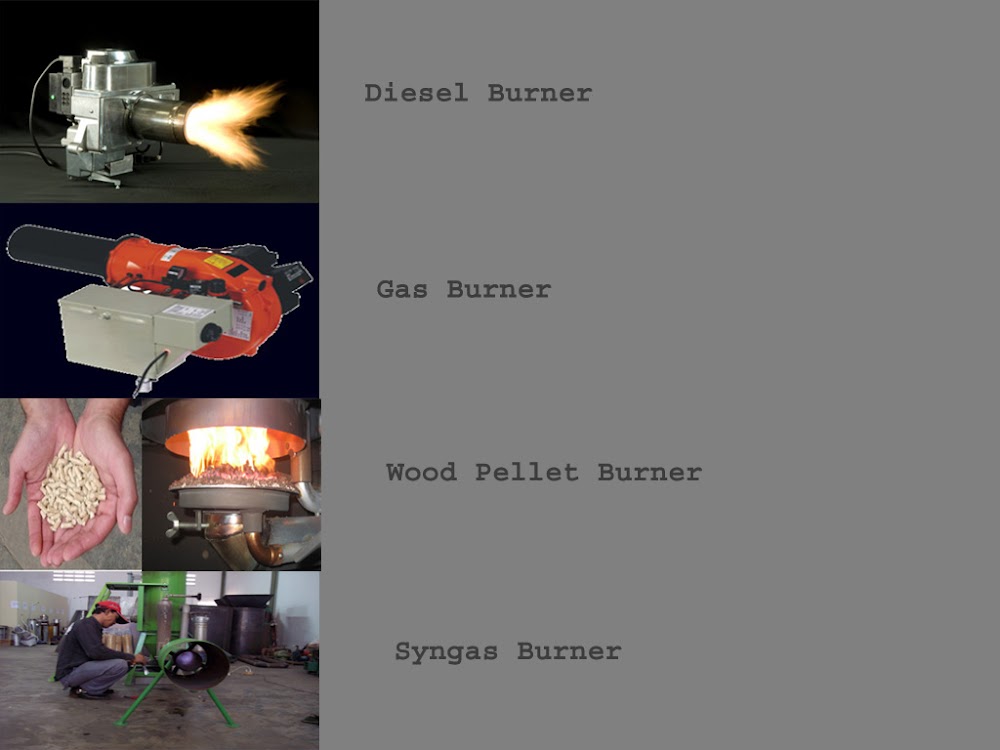

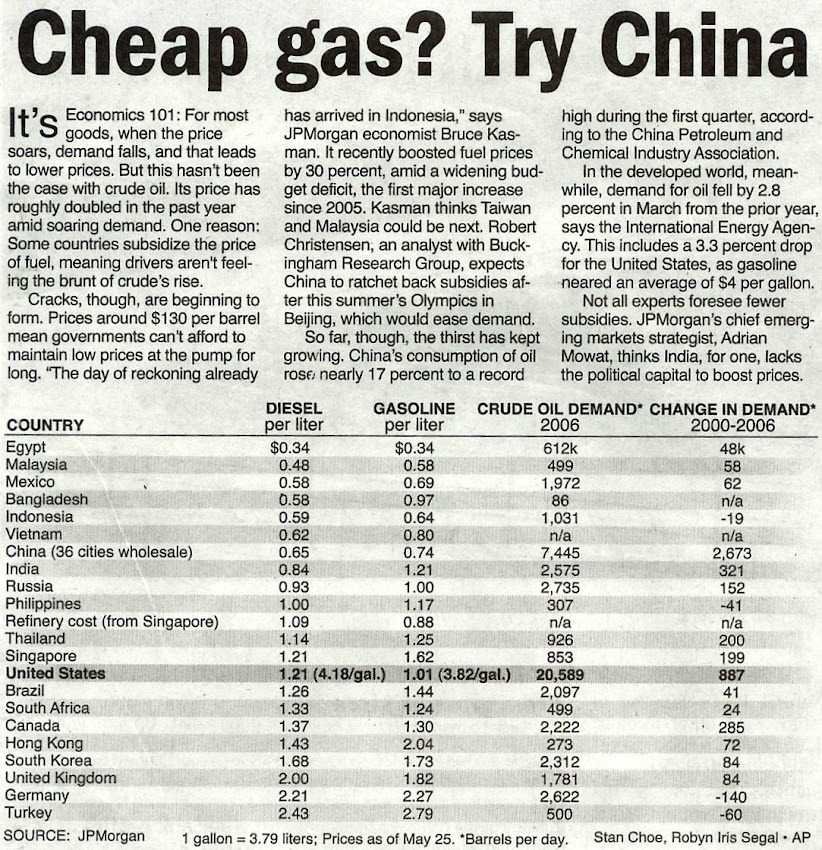

In Malaysia , currently all small and medium size boiler are fuel by either gas or diesel making it environmental unfriendly .

The high number of boiler using fossil fuel are due to the following reasons :

1 ) Previous low oil price at below USD40 / barrel ( around RM1.00 / liter )

2 ) Convenience in handling diesel boiler

3 ) No other alternative ( technology & supplier of biomass boiler )

4 ) No other suitable fuel for small boiler

5 ) Perception of Biomass Boiler are unclean

Most of the above reasons are currently being solved with new technological advancement and availability of new biomass boiler and suitable fuel ( Wood Pellet or EFB Pellet ) .

We plan to introduce this type of pellet boiler for industrial user in Malaysia with our wood pellet .

Pricing start from RM75,000 for 200,000 kCal / hour to RM200,000 for 1,000,000 kCal / hour Wood Pellet Boiler . The low cost are due to mass production for this type of boiler .

Payback are normally within 5 month to 1 year inclusive of the boiler , FOC after the payback period .

Characteristic of Wood Pellet / EFB Pellet Boiler are as follows :

1 ) Fully automatic with preset temperature needed for the hot water , burner will start and stop at preset level

2 ) 90% efficiency due to it's design and efficient air fuel ratio balance during combustion

3 ) high safety feature without chances of explosion as it uses wood pellet which is less flamable

4 ) very clean burning without smoke although ash need to be dispose off once every week

5 ) space saving as structure of the boiler is compact and sturdy

For the first unit we sell in the Malaysia market , we are giving great discount to promote this technology .

Write to us / Call us NOW ! ! !

Drum Dryer selection are important , many factor affect the cost of the dryer , in this case we believe Drum Dryer Size of Diameter 1.5 meter X Length 9 meter should be enough to dry 2 TPH of sawdust .

Drum Dryer selection are important , many factor affect the cost of the dryer , in this case we believe Drum Dryer Size of Diameter 1.5 meter X Length 9 meter should be enough to dry 2 TPH of sawdust .