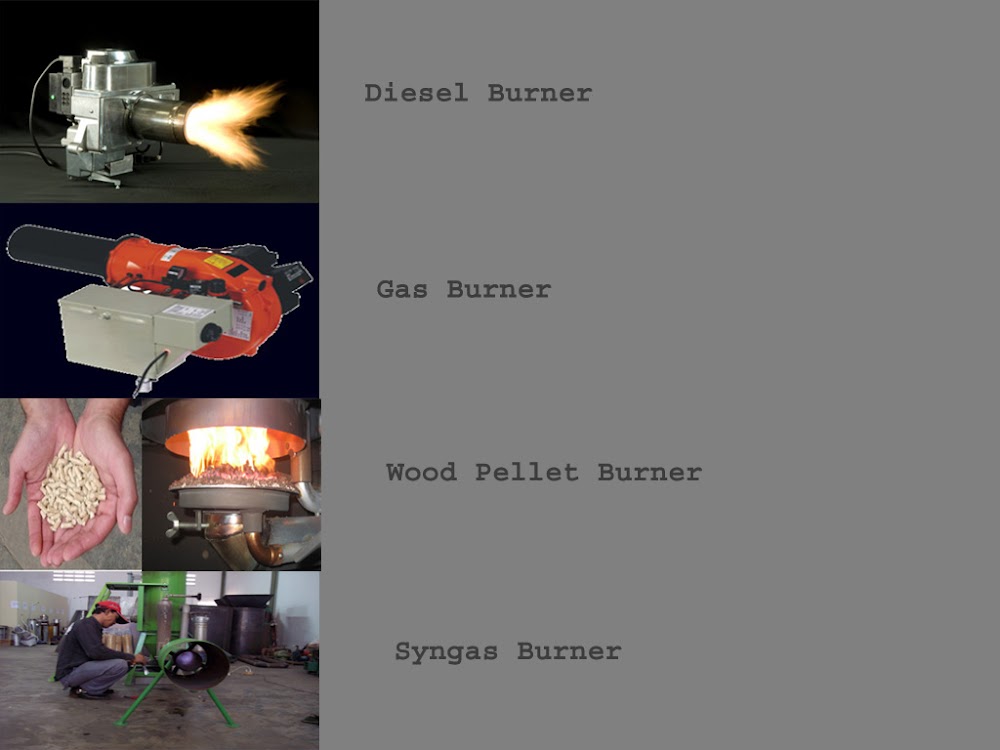

One of the plant we sold have a more advance furnace which reduce manpower and also ease of operation .

As pelleting need very accurate moisture content , the Hot Gas Generator help tremendously especially for big scale operation and also for less experience operator .

The Moisture Content of dust was constantly within ± 1% MC after exiting the dryer . This eliminates one of the most important varible in pelleting , in my previous post I mentioned that MC consistency are very important for good pelleting .

To explain a bit why the Hot Gas Generator helps a lot and normal furnace have it's pertinent issues . Normal furnace feeding of fuel is by hand , worker tend to overfeed the furnace which have small grate , by doing so the worker will have longer time to sit , by doing so too the temperature of the furnace will fluctuate through very wide range which cause drying inconsistency . Hot Gas Generator feed fuel automatically at set parameter and flame in furnace can be control by fan , this will give consistent flame in furnace continuously thus consistent Moisture Content of the sawdust output from dryer .