We have started manufacturing a few weeks ago and everything is going fine with small adjustment here and there . The longer than expected delay are due to testing of various materials available to us like sawdust , wood shavings and rice husk .

During testing , we encounter very big problem with local pelletising materials which we have solved . This have cost us 2 weeks delays and substantial losses . It is a journey to get the correct mix for most optimum production efficiency and yield . There is a saying ' FAILURE IS A FAR GREATER TEACHER THAN SUCCESS '

Production are now ramming up to about 1.2 ton per hour ( TPH ) per unit of Pellet Mill Model SZLH420 which is quite efficient since the supplier only promised us 1 TPH . Operation time for the machine is now 10 hours / day .

If everything is fine we will be trying to get 1.5 TPH in another month or so with 12 hours operation / day giving a total of 36 ton per day volume if raw material is available .

VIDEO - WOOD PELLET PRODUCTION

We are marketing this 2 TPH Full Production Line at RM850,000 with spare parts . Local fabrication and civil work will cost another RM150,000 or so depending on setup . We throw in service and technical advise which is the Most Important part in the setting up of wood pellet plant . Otherwise new player will have big headache in achieving optimum production within a short time .

If you notice in the video , the Plant we have are quite clean in terms of dust control even with all the machineries in operation . Some of the plant setup do not cater for dust control and in the long term it will become health hazard and difficult to maintain staff .

Costing

With this setup , we manage to bring down the total number of worker to only 8 including 2 Supervisor per shift without stoppage during tea time break and also lunch break . This is a huge savings on manpower and also during this difficulty time of getting worker . With time and additional accessories we would be able to cut another 2 worker per shift in a few months time .

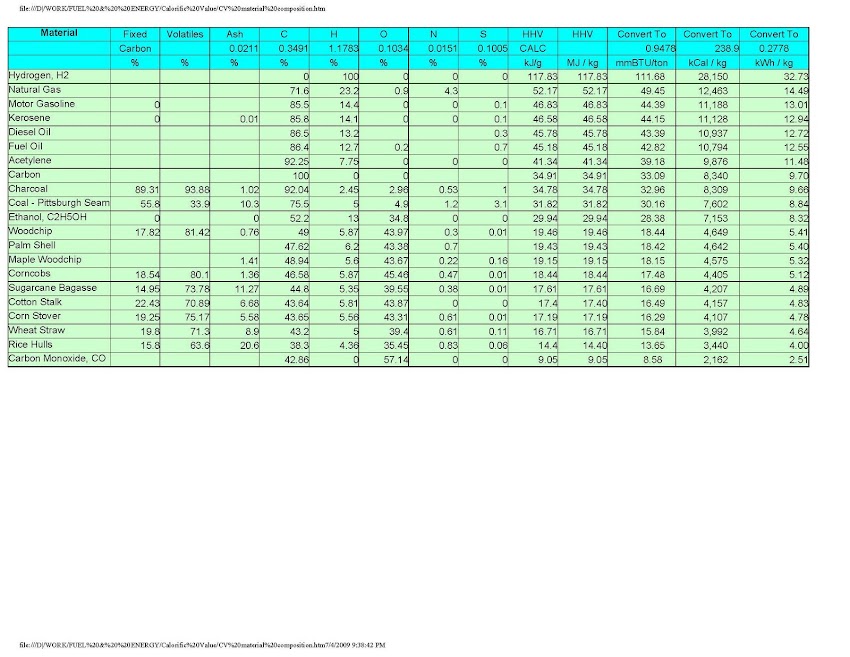

Electricity consumption for the whole plant , at below 300 Ampere consumption is 125kWh of electricity which comes to RM45 / hour for a 2 TPH production . Cost of production per ton will be RM22.50 .

To achieve 1.5 TPH High Quality Wood Pellet consistently , a few problem need to be solve :

1 ) consistently stable moisture content of sawdust

2 ) particle size of sawdust

3 ) good pellet mill and accessories with proper maintenance

4 ) properly design full production line for efficient production

5 ) correct mix of tropical sawdust / rubberwood sawdust

Quality

Quality wise it is above expectation . The Certificate of Test shows that ash is below 1% and Pellet Unit Density is at 1.2 ton / m3 .

This specification is upto Germany DIN Plus Standard on Size , Unit Density , Moisture Content and Ash Content .

Like I said previously , investor need to see for themselves if it is true that the pellet mill can produce 1.2 TPH consistently and operate over long hours without stoppage .

Come visit us to see for yourself .

But no Video & Photos Allowed ( company policy ) .

3 comments:

HI Lee,

I have bought a 300 pellet machine from china. The performance is increased from 100kg/h to 200kg/h after trying it for one month.

Just as u said, roller bearing & jamming in die are normal problems...

To achieve 1.5 TPH High Quality Wood Pellet consistently, a few problem need to be solve :

1 ) consistently stable moisture content of sawdust

For my 300, 11%-13% of MC is the best performance.

2 ) particle size of sawdust

too small is not good.

3 ) good pellet mill and accessories with proper maintenance

4 ) properly design full production line for efficient production

Besides pellet machine, i also bought an air flow dryer. It is hard to reduce sawdust to wanted MC. Sometimes have to dry twice

5 ) correct mix of tropical sawdust / rubberwood sawdust

In your opinion, which kind of sawdust is the most suitable? I found that pellet is easier to be produced by mixing

20-30% rubberwood : 70-80% tropical

I hope you can share your experience, so I can learn from it, thanks!

Gan

Is 300 a flat die machine ?

12 - 15 would be best MC .

Yes too fine sawdust is not good , so adding rubberwood would make it better as rubberwood sawdust are more coarse .

It is too technical on proportion of sawdust mixes , MC , sawdust particle size , die specification and many more variable , you got to study and learn from your mistake based on your material used for pelleting . Everyone would be different due to the above factor .

Yes, it is flat die.

Will try for few more weeks only consider to invest a better machine.

Thanks for your reply!

Post a Comment