STOICHIOMETRY

In layman terms :

Stoichiometry = Perfect Combustion

i.e. Highest Heat Power output at the lowest fuel consumption .

The above graph can be easily explain as follows :

EXCESS FUEL - A lorry laden with overweight goods climbing steep hill , the driver hits the accelerator full throttle but there was no extra power only more black smoke , in such circumstances more diesel escape without full combustion in the engine thus EXCESS FUEL but no extra power . While

EXCESS AIR - In a furnace , say you need 6kg of air to fully combust 1kg of fuel ( normally biomass ) , but you input more air which is at ambient temperature of 30°C while the furnace temperature was 700°C , by channelling too much cold air into the furnace , temperature will drop and thus loss of heat energy .

Please note the grey highlight " Highest efficiency " , the graph show that it is not possible to have perfect combustion ( stoichiometry ) but always burner are design with certain % of excess air , normally 10 to 15% more air to ensure full combustion .

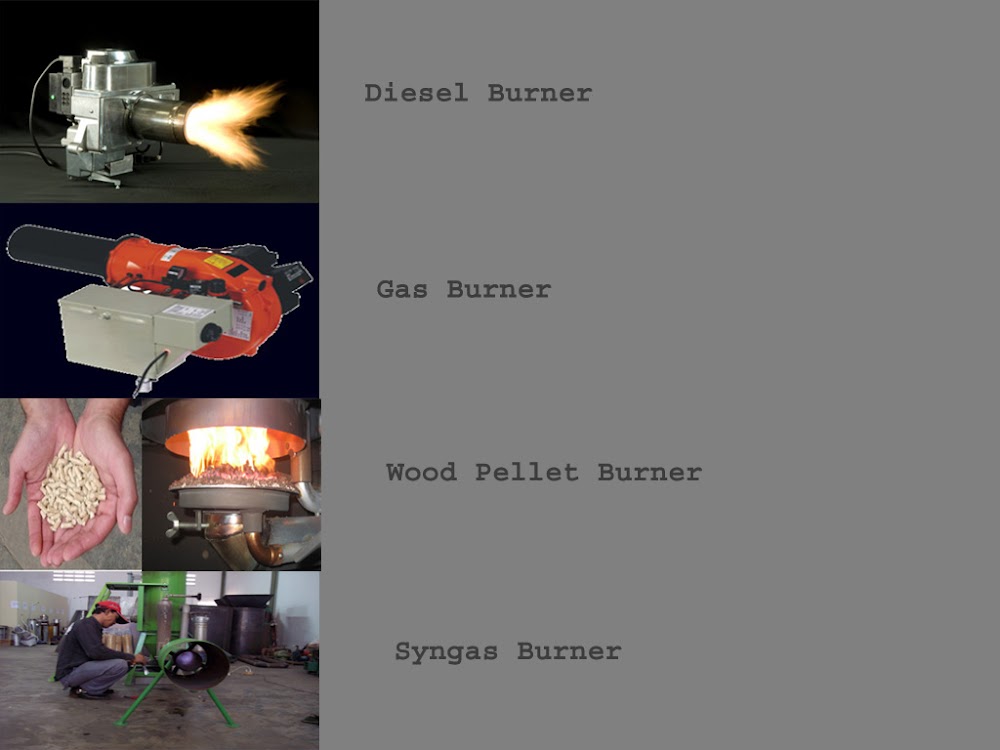

To achieve this , Burner design are critically important . Design of burner take into account factor as follows :

1 ) timing and quantity of fuel feeding

2 ) volume of air corresponding to fuel input

3 ) robustness of burner to ensure low maintenance

4 ) automatic control to achieve highest efficiencies

5 ) safety features of the burner

6 ) simple design but high efficiency

7 ) user friendly

Penny Wise Pound Foolish

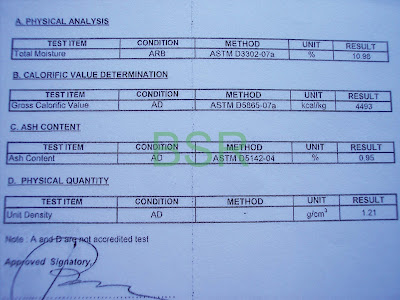

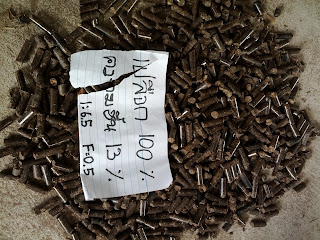

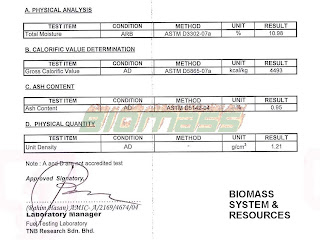

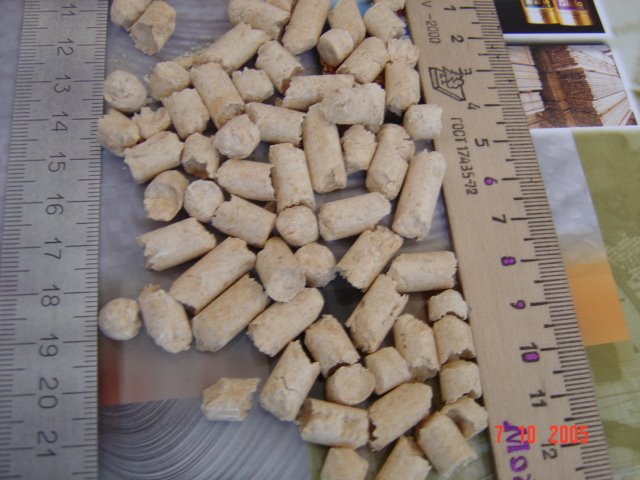

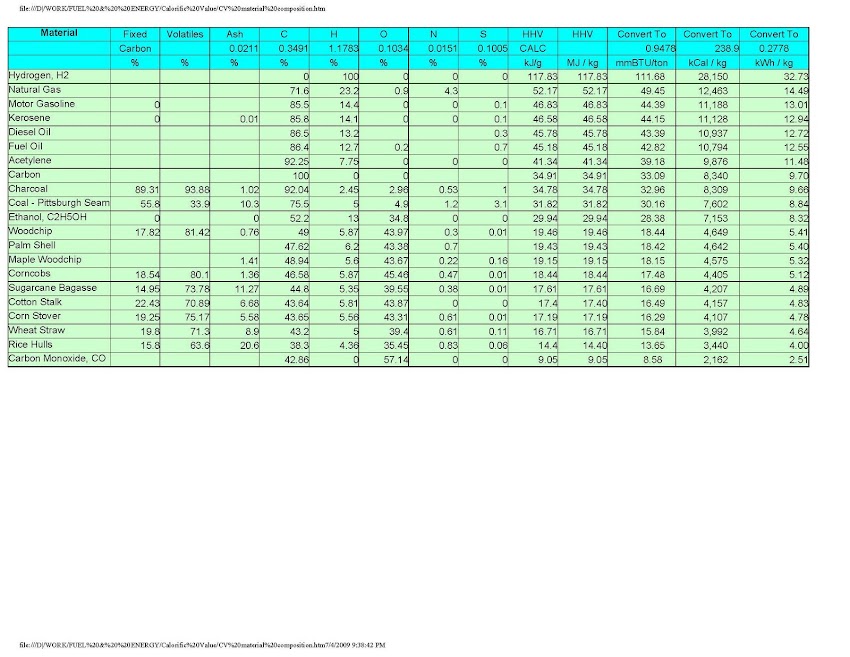

Many executives of companies do not understand this and only think of cheap material to burn in their boiler but in fact not always cheapest biomass wins hands down . Then you got to know the calorific value of the cheap biomass and also the efficiency of burning this cheap biomass . More often than not cheap biomass are very low in calorific value of not more than 2,500 kcal / kg and due to the fluctuation of the Calorific Value it is not possible to have high efficiency during combustion .

I always say this , the boiler man being normal layman will open exhaust valve fully to let more air in so no black smoke in the chimney but by doing so Excess Air will drop the efficiency to below 50% . This means instead of having good burner with efficiency over 80% there will be loss of 30% in combustion efficiency .

So the combination of Biomass Calorific Value and Combustion Efficiency might overwhelm even the cheapest biomass in terms of dollar and cents .

I hope the above will enlighten misconception on pricey biomass .

I hope the above will enlighten misconception on pricey biomass .