Sawdust Drying

We are touching this topic specifically due to it's importance to make good wood pellet unless your sawdust is already dried to 15% Moisture Content ( MC ) .

We are touching this topic specifically due to it's importance to make good wood pellet unless your sawdust is already dried to 15% Moisture Content ( MC ) .If you have gone through our earlier writings , the cost of drum dryer are significant for a Whole Line Wood Pellet Plant . The High price are due to it's big structure and complication in maintaining stable MC sawdust output . Sawdust comes in various MC from 12% to 60% , therefore it is important to control the MC for optimum pelleting otherwise you would not get high standard wood pellet and high production efficiency .

We will now study a typical drying process base on the following conditions :

1 ) Input Sawdust MC 35%

2 ) Output Sawdust MC 12%

3 ) Drying Rate 2 Ton Per Hour Output

To reduce MC from 35% to 12% you would need to evaporate 20% of water , based on 2,000 kg per hour output , water that need to be removed is 600kg and the input sawdust is 2,600 kg/hr .

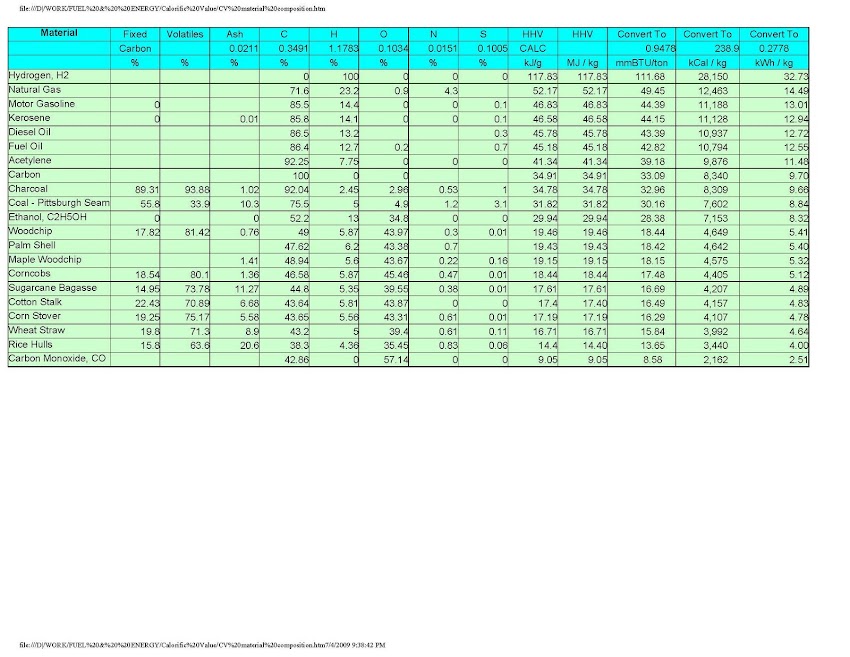

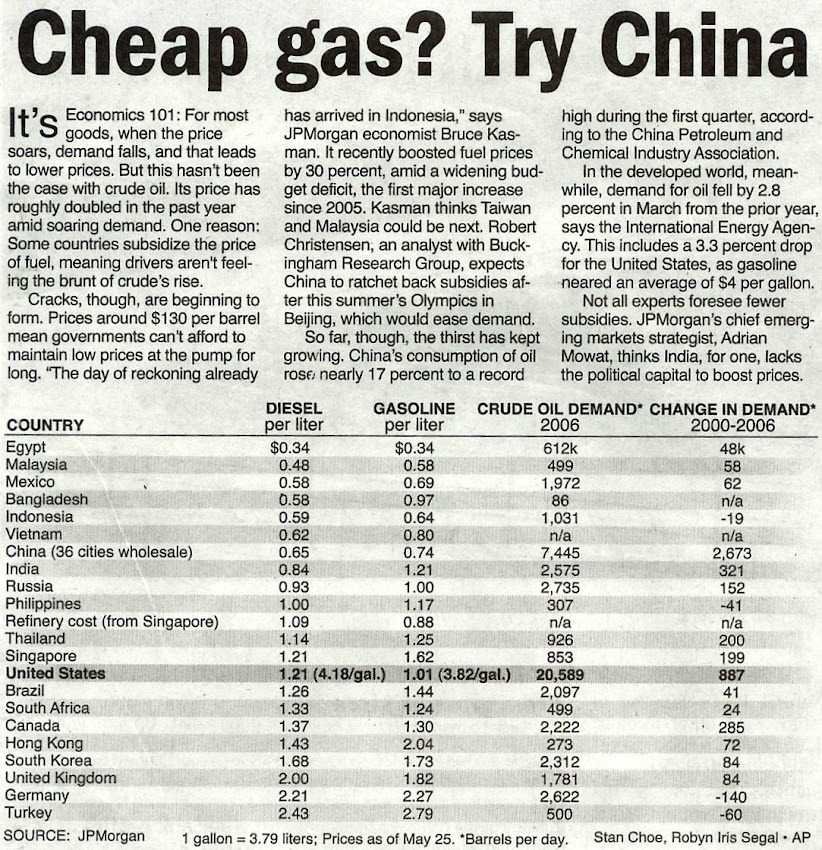

To remove 600kg of water you will need 640kw ( 550,000 kCal/hour ) of energy which is equivalent to burning 200kg/hour of wood offcut . In short 100kg/hour need to be combusted to dry 1 TPH ( output ) sawdust . Cost of drying would be about RM5 / ton sawdust if your offcut cost is RM50 / ton .

The Calculation Chart below is from ASPENTECH software and reconfirm by manual calculation which I did not show here due to it's tediousness of calculation , suffice to say the input data , output data and design of the dryer are correct .

Drum Dryer selection are important , many factor affect the cost of the dryer , in this case we believe Drum Dryer Size of Diameter 1.5 meter X Length 9 meter should be enough to dry 2 TPH of sawdust .

Drum Dryer selection are important , many factor affect the cost of the dryer , in this case we believe Drum Dryer Size of Diameter 1.5 meter X Length 9 meter should be enough to dry 2 TPH of sawdust .Cost of this dryer should be around RM200,000 landed in Malaysia c/w stove , electrical panel and cyclone .

We hope to use this Dryer and the Pellet Mill to make EFB Pellet once we have started Wood Pellet Production probably in August 2011 .

No comments:

Post a Comment