Whole Line Wood Pellet Mill Plant

As promised , today I will be writing about Densification of Wood Biomass to make Wood Pellet .

Wood Pellet can be made of wood sawdust , wood shavings , timber offcut and woodchip .

The purpose of Densification are as follows :-

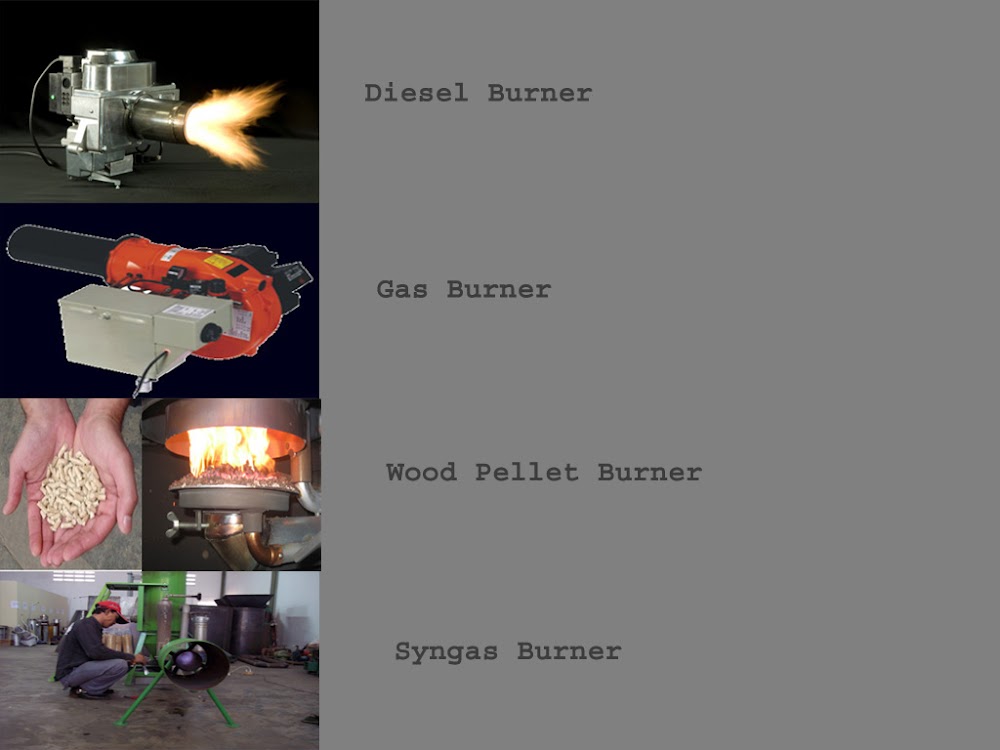

1 ) common size - enabling automation ( automatic feeding and burning just like diesel/gas burner with high efficiency )

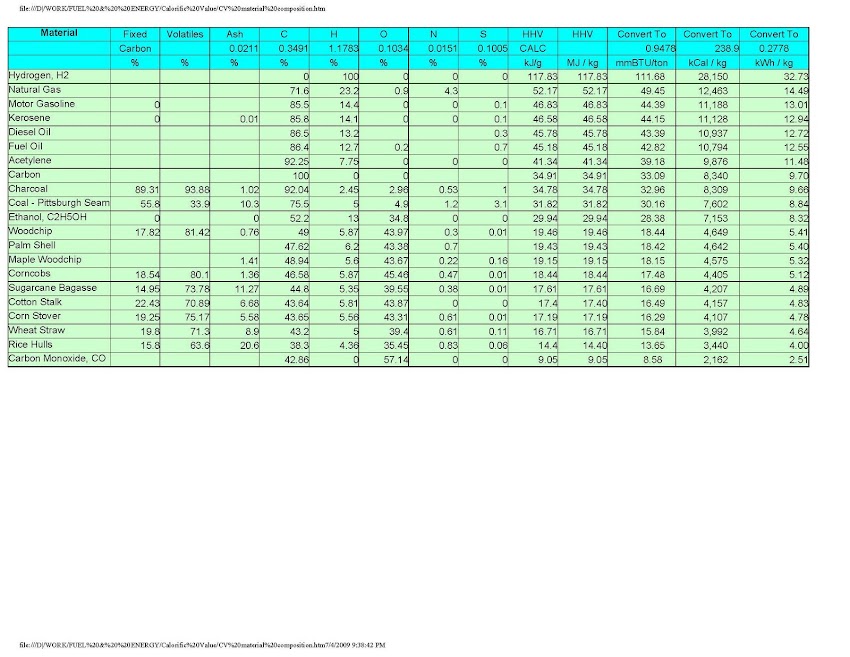

2 ) high calorific value - optimum combustion efficiency ( 90% efficiency is possible )

3 ) high density - lower transportation and storage cost

To achieve the above purpose , Feed Mill Machines have been turn to make wood pellet with some modification as wood have higher density and more difficult to be pelletised compared to animal feed .

Unless you are setting up large size Pellet Mill Plant of 20 TPH , small machineries from China would be more suitable due to their much more lower cost .

From our studies of wood pellet processing , optimum size of operation should be of 2 TPH to 5 TPH due to the availability of raw material , operation cost , profit margin and marketing .

Let's take a closer look at a 2 TPH Whole Line Wood Pellet Plant .

It will include sectional processing as follows :

1 ) Material Processing - Hammermill , Screener - RM75,000

2 ) Drying - Drum Dryer - RM180,000

3 ) Pelleting & Conditioning - Pellet Mill , Conditioner / Cooler - RM160,000

4 ) Packing - Storage Bin , Packing Machine , Weighting Scale - RM30,000

All the Segment above can be connected with belt conveyors , screw conveyors or bucket elavator to make it fully automated with only 5 workers during operation . Additional cost for this could be around RM150,000 .

Electrical , Local Fabrication , Installation Cost , Training will cost another RM120,000 .

Provision for 6 months Spare Parts and Miscellanous will cost RM50,000 .

The above is indicative cost of setting up a Whole Line Wood Pellet Plant based on 2 TPH production .

You could refer to the side bar and the bottom for some pictures of the above machineries .

Call us if you need further consultation .

No comments:

Post a Comment