2 Ton Per Hour Pellet Plant

We are a bit delayed in the installation of our 2 Ton Per Hour ( 2 TPH ) Whole Line Wood Pellet Plant . New date for commissioning have been push back to End of April 2011 .

Lots of minor problems with China Whole Line Design and Installation .

I admit we overlook a few areas and also the professionalism of China Machinery Supplier are in doubt especially in Project Management and also the linkage between each section in the Whole Line Plant .

But in the process we also learn a lot for our future expansion plan and possibly our new 2nd line maybe in 6 month to 1 year time .

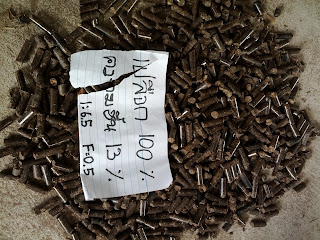

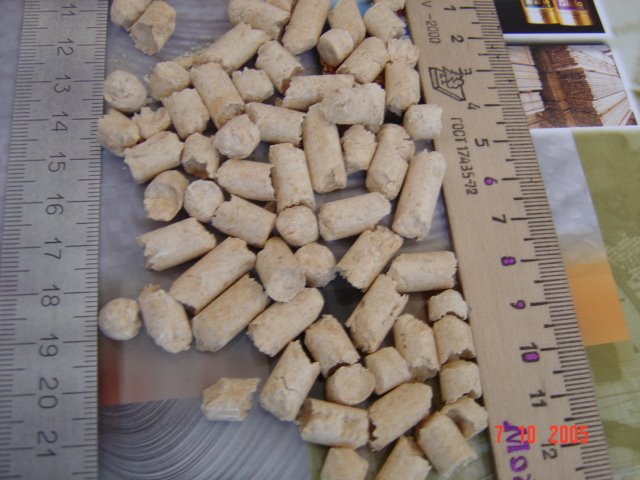

We now believe that our pellet mill are one of the best from China and hopefully when it is in production it should give us above 1.2 TPH for the Model 420 unit with minimal maintenance .

Here are some of the photos during installation of machineries at my plant .

Current Pellet Mill / Pellet Mill Plant from China have the following problems :

a ) Pelet Mill Die cracking after short time of usage

b ) Roller Bearing need constant change

c ) Constant Jamming in the Pellet Mill Die Chamber

d ) Low Density of Wood Pellet Produced

e ) Sawdust need additives during production to ensure smooth output of pellet from Pellet Mill

We also found out that many China supplier are not genuine factory owner which means they buy and sell the machineries , thus technical wise they are not up to standard unless they are supplying the best machines from the best fabricator . Normally this is not the case as the buyer will haggle about pricing , therefore the supplier will tend to get the cheaper machines which will create problems in the end . How would you know which is the best machines from China , there is more than 100 supplier of pellet mill machineries from China , everyone say they supply the best . Unless you want to CAMP there to search for the best machines . For the record , I did 3 tour of duty to China to search for the best machineries .

Pre-requisite of establishing a Wood / EFB Pellet Manufacturing Business :

1 ) Stable source of sawdust or EFB

2 ) Total Investment - RM1 Million including machineries , electricity supply , local steel fabrication , forklifts & etc for a 2 TPH Whole Line Plant

3 ) Some technical knowledge on machineries

4 ) For now , market should not be a problem , it is a matter of pricing

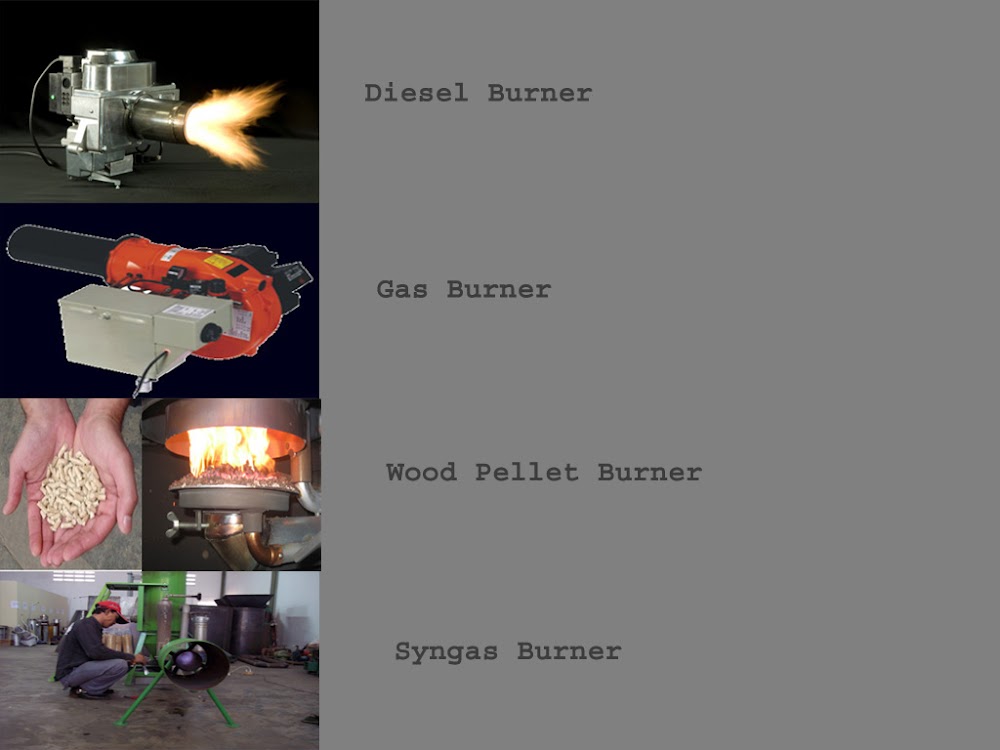

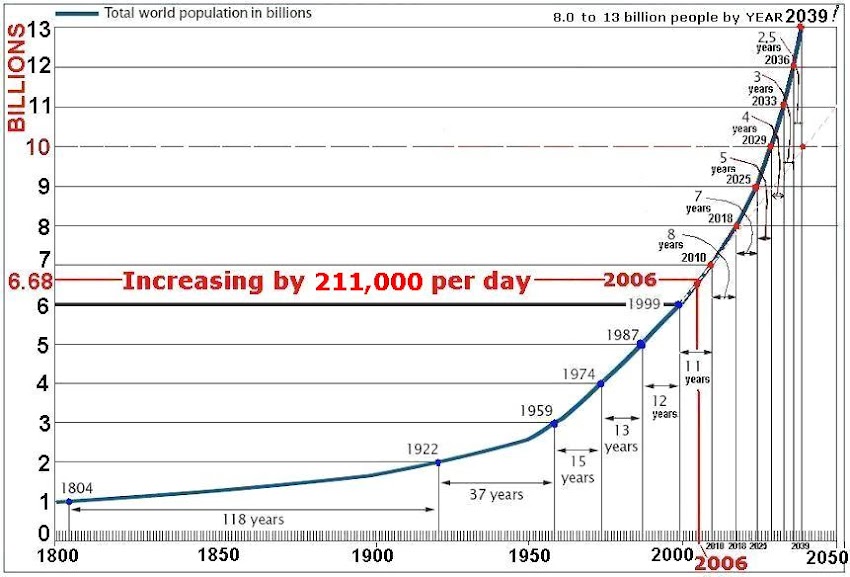

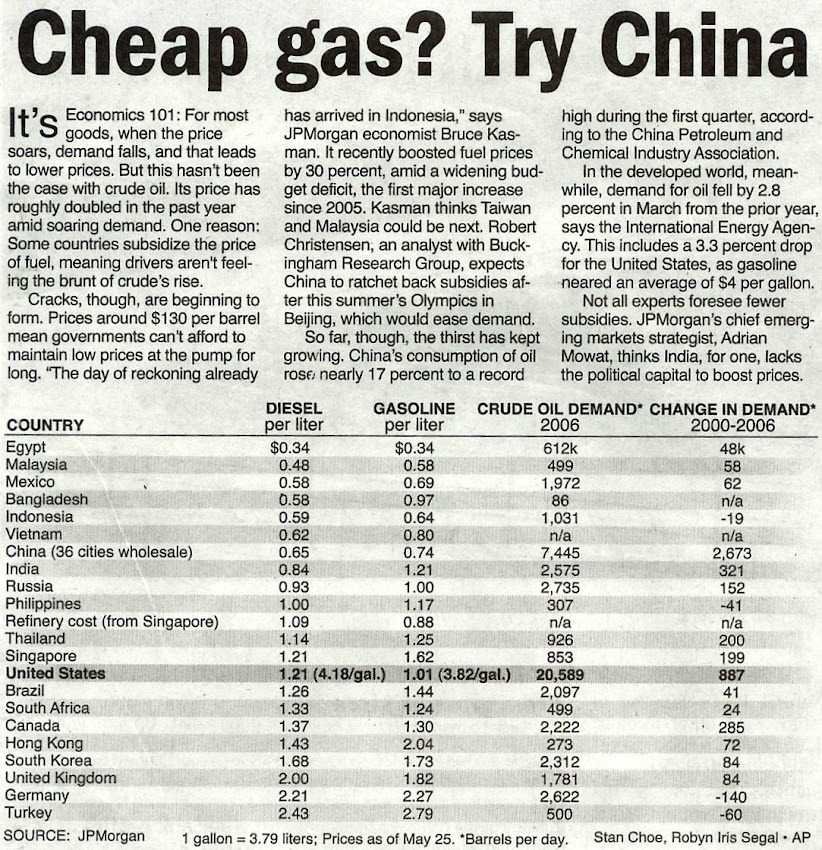

Lately ( the last 3 months ) , my blog have generated tremendous search for wood pellet maybe due to the current high price of fossil fuel which at the time of writing , Nymex Oil Futures is at over USD100 per barrel . Inflation in China is also causing a problem as Wood Pellet Plant pricing have also increase from initial RM750,000 earlier to over RM850,000 now , at last count . Sawdust price have also been increasing locally . If price continue to rise , it might not be viable anymore to invest in Wood Pellet Business unless Wood Pellet price play catch up in the near term .